History

Beginning of the FlexoForce company. Registration as a resident of the Free Economic Zone "Minsk". Organization of the printing process on the basis of a narrow-format printing machine Edale 250S. The main profile of the company is the production of self-adhesive labels

Acquisition of the first large format printing machine Bielloni (Italy). From this point on, the expansion of FlexoForce's presence in the field of flexible packaging begins. Production is organized in rented areas. Over the next 10 years, the development of production will be represented by three Bielloni printing machines with a total output of up to 200 tons of flexible packaging.

Organization of production on our own premises. A production complex with an area of over 3000 m2 was put into operation. Start of strategic cooperation with Comexi (Spain). Acquisition of the company's first large format 8-color press. Over the next 3 years, the equipment fleet is supplemented by a 10-color printing machine. The total production volume is up to 350 tons of finished products.

Start of implementation of process automation and resource management systems. Strategic interaction with the products of 1C company (Russia). Implementation of 1C ERP (CRM) systems and modules. Completion of the formation of a complete production cycle. Collaboration with Esko. Launch of plate making equipment.

Modernization of the production complex. Expansion of production and storage areas up to 4500 m2. Purchase of Comexi 8-color printing machine. The total production volume is up to 500 tons of finished products.

The ecological component of FlexoForce has been significantly increased. The equipment was put into operation, allowing to exclude harmful emissions from the printing industry into the atmosphere. Installed closed systems for the automatic regeneration of solvents and their return to the production cycle. The efficiency of separating waste films for subsequent processing has been increased.

2020 can be safely called the year of strength testing of the organizational system of FlexoForce. The mode of action in the context of COVID-19 has made a number of evolutionary transformations in the process system of the company's functioning. For some employees, a permanent remote work profile has been introduced. Work continues on deep optimization of the printing process. The equipment is being modernized to work with variable data of the CHESTNY ZNAK system (Russian Federation).

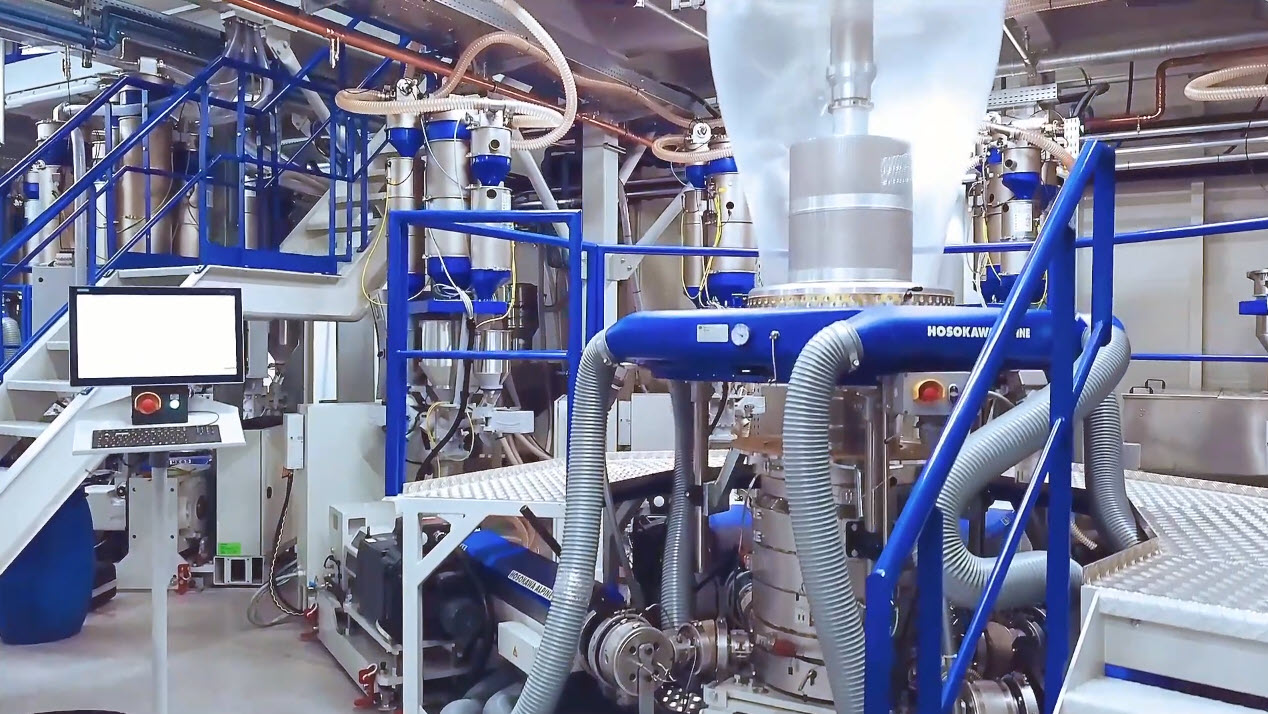

FlexoForce's depth of finished product processing has been supplemented by in-house film extrusion and metallization facilities. Combined, this increases the reliability of FlexoForce flexible packaging production for our end customers, and provides much greater opportunities to create customized flexible packaging solutions for interested market players.

Strengthening of FlexoForce research potential. A time of active competence building in studying the properties of polyethylene-based films. Formation of our own laboratory to study special properties of packaging materials in order to understand the necessary and sufficient level of food packaging parameters for our customers.

Implementation of automated systems In-Date - planning with guarantee of accurate deliveries and In-Sight - informing customers about the status of placed orders. From now on, our Partners can not only be even more confident that the packaging will be ready for shipment within the agreed timeframe, but also directly monitor the status of orders until they appear in the finished goods warehouse.